Hoja de Corte Ideal Edge para Encimeras

Descripción General del Producto

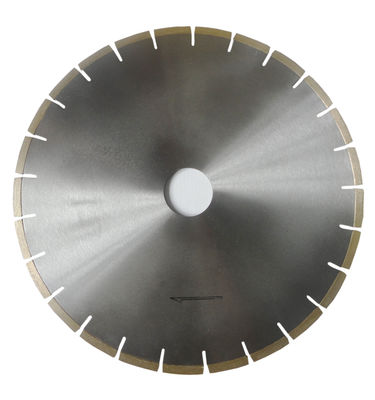

Logre la perfección en la fabricación de encimeras con nuestra Hoja de Corte Ideal Edge para Encimeras, diseñada específicamente para una calidad superior en el recorte de bordes en trabajos de corte de encimeras de granito y mármol. Diseñadas para fabricantes de piedra profesionales, estas avanzadas hojas diamantadas ofrecen una nitidez de corte y una eficiencia de recorte excepcionales, garantizando al mismo tiempo resultados sin astillas en ambos lados del corte.

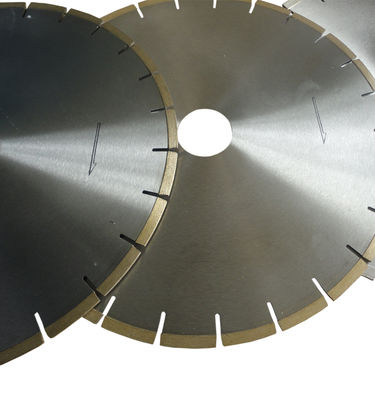

Especificaciones Técnicas

| Nombre del Producto |

Diámetro (mm) |

SteelCore (mm) |

Dimensión del Segmento (mm) |

Número de Segmentos |

Aplicación |

| Hoja de Corte de Bordes |

300 |

2.2 |

43/41*2.8*10 |

22 |

Granito, Cuarzo, Mármol |

|

350 |

2.2 |

43/41*3.2*10 |

25 |

|

400 |

2.4 |

43/41*3.6*10 |

29 |

Características y Beneficios Clave

1. Calidad de Recorte de Bordes Ideal en Trabajos de Corte de Encimeras de Granito y Mármol

- Segmentos de Precisión: Optimizados para el perfilado y recorte de bordes de encimeras

- Calidad Profesional: Cumple con los estándares de la industria para la fabricación de encimeras de alta gama

2. Mejor Nitidez de Corte y Eficiencia de Recorte, Sin Astillado en Doble Cara

- Granos de Diamante Premium: Partículas de diamante de alta calidad para cortes rápidos y limpios

- Matriz de Unión Avanzada: Especialmente formulada para las características del granito y el mármol

- Tecnología Anti-Astillado: Diseño especial de bordes que evita el astillado de entrada y salida

- Protección de Doble Cara: Asegura cortes limpios en las superficies superior e inferior

Hojas Universales para Encimeras

- Matriz de Unión Media: Adecuada para todo tipo de piedra

- Aplicación Versátil: Granito, mármol, cuarzo, piedra reconstituida

- Rentable: Una hoja para múltiples materiales

Servicio Postventa

- Soporte Técnico: Asistencia en línea 24/7

- Consultoría de Aplicación: Selección óptima de hojas

- Capacitación de Uso: Tutoriales en video y documentación

- Solución de Problemas: Soporte experto para la resolución de problemas

Preguntas Frecuentes

P: ¿Qué hace que estas hojas sean ideales específicamente para el trabajo en encimeras?

R: Nuestras hojas presentan perfiles ultrafinos y formulaciones de unión especializadas diseñadas específicamente para la precisión requerida en la fabricación de encimeras, lo que garantiza bordes sin astillas y un desperdicio mínimo de material.

P: ¿Pueden estas hojas manejar tanto granito como mármol de manera efectiva?

R: Sí, ofrecemos formulaciones específicas para cada material: unión dura para granito y unión blanda para mármol, además de opciones universales que funcionan excelentemente en ambos tipos de piedra.

P: ¿Cómo evito el astillado al cortar los bordes de las encimeras?

R: Utilice la velocidad de la hoja correcta, asegúrese de una alineación adecuada de la hoja, corte desde el lado terminado cuando sea posible, mantenga una velocidad de avance constante y utilice nuestro diseño de hoja anti-astillado.

P: ¿Cuál es la diferencia entre la serie estándar y la premium?

R: La serie premium ofrece una vida útil un 30% más larga, una velocidad de corte más rápida y una calidad de borde superior. Son ideales para talleres de fabricación de alto volumen y proyectos de encimeras premium.

P: ¿Debo usar agua al cortar los bordes de las encimeras?

R: Se recomienda el corte en húmedo para obtener los mejores resultados: prolonga la vida útil de la hoja, reduce el polvo, evita el sobrecalentamiento y proporciona los cortes más limpios, especialmente importante para los bordes visibles.

¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!  ¡Su mensaje debe tener entre 20 y 3.000 caracteres!

¡Su mensaje debe tener entre 20 y 3.000 caracteres! ¡Por favor revise su correo electrónico!

¡Por favor revise su correo electrónico!